Help Centre

Have a technical question or issue about gaskets and sealing? Unsure about chemical resistance, temperature, or pressure? Take a look at our help centre.

Contact Us

Need a price for a standard or bespoke part? Why not send us a quotation request.

Bespoke Gaskets

Bespoke gaskets (specials) can be manufactured from any material; to any shape, size, thickness and dimension.

We can manufacture from sketch, sample, technical drawing, .dxf, .pdf, .step, or description.

As a general rule; you should select the thinnest material possible, for your application.

Temperature, pressure and application help direct you to the ideal solution for your sealing requirement.

If you require a gasket to your own dimensions, please contact us for a competitive quotation.

Examples of materials we can manufacture bespoke gaskets from include:

- Cork

- Foam

- Graphite

- Leather

- Non-Asbestos

- Paper

- PTFE

- Rubber

(We stock hundreds of variants).

Bespoke gaskets can be manufactured for many projects, our specialties include:

- Covers

- Doors

- Exhausts

- Manifolds

- Manways

- Pipes

- Sumps

- Windows

Cover gaskets are used in engines to contain oil as it flows through the system. We manufacture cover gaskets, both rocker and valve cover in nitrile, cork and non-asbestos materials. Choice of material depends on several factors such as pressure, flange width and materials surrounding the seals. Please contact us for technical advice.

We can work from technical drawing, sketch, sample, .dxf, .pdf or description.

With no minimum order quantity, we will manufacture one-off specials.

We offer our customers complete material certification and traceability. Our quality system even allows for customers to control how their parts are manufactured.

We manufacture door gaskets and seals – e.g. for electrical enclosures.

We offer our customers complete material certification and traceability. Our quality system even allows for customers to control how their parts are manufactured.

We can manufacture from sketch, sample, technical drawing, .dxf, .pdf or description.

Please contact us for a quotation.

Exhaust Gaskets

We manufacture exhaust gaskets, commonly from graphite materials. With no minimum order quantity, we will manufacture one-off specials.

We can work from technical drawing, sketch, sample, .dxf, .pdf or description.

We offer our customers complete material certification and traceability. Our quality system even allows for customers to control how their parts are manufactured.

We manufacture gaskets for classic cars and vintage automobiles. We produce all sorts of gaskets for engines, transmissions, sump and exhaust systems. Many materials are used for gaskets in classic cars, please consult our gasket materials or contact us with your specific requirements.

With no minimum order quantity, we will manufacture one-off specials. Although, if you are part of a car club, getting together and ordering a larger quantity will prove more economical.

We can work from sketch, sample, technical drawing, .dxf, .pdf or description.

Please send us a request for a quotation.

We manufacture heat exchanger gaskets for a wide range of equipment.

Choosing the correct gasket material depends on the operating conditions; such as temperature, pressure and what materials the gasket is in contact with. Please contact us for technical help and advice.

Common examples of materials and types of gaskets used for heat exchangers include (but are not limited to):

- Rubber

- Non-Asbestos Fibre

- Graphite Foil

- Spiral Wound

- Solid Metal Joints

We can work from technical drawing, sketch, sample, .dxf, .pdf or description.

With no minimum order quantity, we will manufacture one-off specials.

We offer our customers complete material certification and traceability. Our quality system even allows for customers to control how their parts are manufactured.

We manufacture manifold gaskets from rubber, cork and graphite materials.

Manifold gaskets are responsible for sealing the intake manifold in an engine against the cylinder heads.

We can work from technical drawing, sketch, sample, .dxf, .pdf or description.

With no minimum order quantity, we will manufacture one-off specials.

We offer our customers complete material certification and traceability. Our quality system even allows for customers to control how their parts are manufactured.

We manufacture manway gaskets for a range of applications: for example, for fuel tanks and vessels. Gaskets can be produced as specials and in the material required to meet the specifications of the tank.

If you are servicing a tank and order before twelve o’clock, we can arange delivery to site the following morning.

We can work from technical drawing, sample, sketch, .dxf, .pdf or description.

With no minimum order quantity, we will manufacture one-off specials.

We offer our customers complete material certification and traceability. Our quality system even allows for customers to control how their parts are manufactured.

We manufacture oil gaskets, e.g. from nitrile rubber or gasket paper – resistant to solvents, fuels, biofuels etc.

With no minimum order quantity, we will manufacture one-off specials.

We offer our customers complete material certification and traceability. Our quality system even allows for customers to control how their parts are manufactured.

We manufacture and supply pipe gaskets, otherwise known as flange gaskets, in a range of materials. We hold dedicated tooling for the majority of standard sizes and tables and can manufacture special or one-offs to your own measurements and specifications. If you can’t find the information you’re looking for here, or wish to place an order then please contact us. The prices of pipe gaskets depend upon volume, material and thickness so please contact us for a quotation.

Different Types of Pipe Gaskets

The most commonly used gaskets in piping are standard flange gaskets in rubber or fibre, or spiral wounds. For particularly large pipes, gaskets can be manufactured in segments of rubber and joined together.

Standard Sizes and Dimensions

Pipe gaskets are made to fit the size of standard pipes or flanges. The most common standards are BS10 (British/Australian), PN/DIN (European), ASA/ANSI (USA) and JIS/KS (Japanese/Korean).

For ease of reference you can download some of the most common pipe gasket dimension charts here.

- Gasket Tables for PN Designated Flanges (DIN)

(To BS EN 1514-1:1967. PN 6, PN 10, PN 16, PN 25, PN 40)

- Gaskets for Class designated Flanges Suitable for ANSI Standard Flanges (ASA)

(To BS EN 12560-1:2001: ASME B16.21 Class 150, Class 300, Class 600; ASME B16.47 A Class 150, Class 300, Class 600; ASME B16.47 B Class 150, Class 300, Class 600)

- Gasket Tables for BS10 Flanges

(To BS 3063:1965: Table A, Table B, Table E, Table F, Table H, Table J, Table K)

Material Selection

Pipe gaskets can be manufactured from many different gasket materials. The right material to use depends upon the application and the environment in which the gasket will be used. The contents of the pipe, including the range of temperatures and pressures under which it is expected to operate will dictate material selection. Material specification should also take into account the flange being used. If you are in doubt about which material you need, please contact us for technical support.

A non-asbestos fibre or graphite material can be specified for steam applications. For diesel or other fuels a non-asbestos fibre or quality nitrile rubber (BS 2751) should be used. Because of the extra additives in modern fuels, lower grade nitrile can be affected and break down. This is mistakenly blamed on the fuel itself when in reality it is caused by the corrosive nature of the additive.

If you are specifying for a particular chemical then please see our guide to gasket chemical resistance.

What is the Minimum/Maximum Thickness for Pipe Gaskets?

The thickness of a pipe gasket is governed by several requirements. The condition of the surface of the flange face has an important part to play. A thicker gasket may be required for a poor quality surface, as it will flow into and takes up the deformities on the face ensuring a good seal. With a clean and smooth flange face, a thinner gasket can be considered.

Pressure and media are other factors that can decide the thickness of gasket required. Putting too thick a gasket into a flange joint will increase the surface area that the system pressure can work against. For this reason, as a general rule: the thinner the gasket the better.

Common thicknesses of gasket material for pipe flanges are 1.5mm and 3mm.

Full-Face or IBC Gaskets

Pipe gaskets can be either full-faced or inner bolt circle (IBC). Full faced gaskets have bolt holes in them and cover a large part of the face of the flange. IBC gaskets, otherwise known as ring-type or raised-faced joints, sit inside the bolts fastening the pipe flanges.

What Standards Cover Pipe Gaskets?

The most common standards are:

- BS10:2009: British Standard specification for flanges and bolting for pipes, valves and fittings.

- DIN: Deutsches Institut für Normung (the German Institute for Standardisation).

- ANSI: the American National Standards Institute.

- ASA: the American Standards Association (now ANSI).

- ASME: the American Society of Mechanical Engineers The ASME B16.47 Series A and B took over from MSS SP-44 (Series A) and API 605 (Series B)

- ISO: International Organisation for Standardisation.

- JIS: Japanese Industrial Standards.

British and European Standards

The current standard for use in the UK and Europe is BS EN 1514-1:1997. This standard took over from BS 4865-1:1989 for PN flanges.

Other standards include:

- BS EN 12560-1:2001: Flanges and their joints. Gaskets for Class-designated flanges. Non-metallic flat gaskets with or without inserts

- BS EN 12560-2:2013: Flanges and their joints. Dimensions of gaskets for Class-designated flanges. Spiral wound gaskets for use with steel flanges

- BS EN 12560-3:2001: Flanges and their joints. Gaskets for Class-designated flanges. Non-metallic PTFE envelope gaskets

- BS EN 14772:2005: Flanges and their joints. Quality assurance inspection and testing of gaskets in accordance with the series of standards EN 1514 and EN 12560

Made to Measure Flange Gaskets

Some pipes or tanks are fabricated for particulat purposes and as such do not conform to set standards and dimensions. For these situations we manufacture bespoke pipe gaskets in either small batch quantities or as one-off specials.

If you are in any doubt as to whether you require a standard size or a special then please contact us with the dimesions and we will be able to tell you. See below for more information on how to specify a gasket.

How to Specify a Pipe Gasket

If you know the standard size of gasket you require then we will simply need to know: the material required; the thickness required; whether you need full-faced or IBC gaskets and the quantity.

If the part is a special, in addition to the above information we will also need to know: the outer diameter (O.D.), the inner diameter (I.D.), the pitch circle diameter (P.C.D.) and the number of holes.

We may also need to know: the operationg conditions (chemical resistance required, operating temperature, operating pressure and state of the flanges).

Increasing Chemical Resistance

The chemical resistance of a pipe gasket can be increased by being lined with a PTFE envelope, or bore-liner. This is a much more cost effective alternative than using a solid PTFE gasket. The PTFE envelope fits over the pipe gasket and serves to protect it from decomposition by the aggressive chemicals in the pipe. If you have particular chemical resistance requirements then please let us know when you specify your gasket.

Torque Settings

Torque settings are determined by the type and thickness of the flange material, the bolt material and by the gasket material. The correct torque settings for the flange bolts should be sourced from the flange supplier/manufacturer or the pipe system designer.

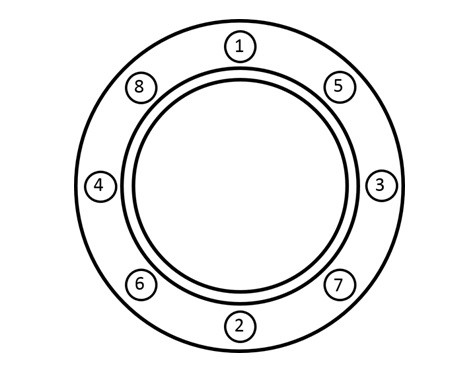

Flange Bolt Tightening Sequence

To obtain a leak-free flange connection a proper gasket installation is needed. The bolts must be given the correct bolt tension and the total bolt strength must be evenly divided over the whole flange face.

On the first pass lightly tighten the first bolt then the bolt directly across, or 180º from the first bolt. Move 90º round the pipe for the third bolt and then directly across for the fourth. Continue this sequence until all bolts are tightened.

More information can be found in our gasket fitting guide.

The above information should only be used as a guide. Please contact RAM to discuss your application.